Cleaning diagnostics

In general, the manufacturing processes used on electronic assemblies are a series of chemical processes. Each step in the operation has the potential for leaving harmful materials on the PCB that can compromise assembly reliability. Cleaning is often needed to remove such harmful residues and improve reliability.

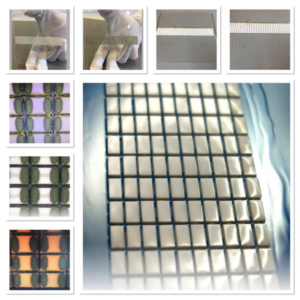

It is important to thoroughly clean electronics after production to ensure their optimal functioning and longevity. Some electronics are a crucial component of various systems and devices, which rely heavily on their precision and accuracy. As such, any residual debris or contaminants can cause malfunctions or inaccuracies that can impact the performance of the entire system. By conducting a careful and thorough cleaning process, technicians can remove any potential sources of issues and ensure that the electronics are operating at full capacity. This process can involve various techniques and cleaning agents tailored to the specific needs and materials of the electronics, and should be completed by skilled and experienced professionals to ensure safety and effectiveness. Overall, proper cleaning can greatly improve the consistency and reliability of various systems, while also extending the lifespan of these important components.

How can we help you with our cleaning diagnostics?

- Flux residues dynamic solubility testing and comparison

- Statistical process control of cleaning process according to J-STD-001 par. 8

- Validation of changes instead of ionic contamination measuring

- Cleaning process optimization

- Cleaning machine capability studies

- Cleaning process diagnostic