Inspection Services

Every year, hundreds of consumer electrical and electronic goods get recalled, dealing serious reputational and financial damages to brands and retailers. The most common causes of recalls are safety-related, including overheating, electric shock and explosion. In most cases, these faulty products can be traced to low-cost manufacturing destinations.

ETECH’s Inspection services will help protect your brand and your company’s reputation by minimizing defective merchandise, customer complaints, non-compliant products, and late shipments.

It is imperative that manufacturers verify that the products manufactured, shipped and distributed under their brand name meet industry, government regulations or their own specific requirements. As an independent, third party inspection and testing company, ETECH can conduct a variety of inspections to ensure that your brand, reputation and consumers are protected.

Our in-depth inspections are based around industry accepted practices and standards combined with extensive experience with product reliability and potential sources of defects, providing the most complete data possible about your product and its construction.

Possible visual inspections:

Printed Boards

An examination/inspection of bare printed circuit boards (PCBs) consists of the visual interpretation of the conformity/compliance with the minimum requirements described in the various specifications of the printed circuit boards, such as for example; customer-specific criteria, IPC-6010, J-STD-003, IPC-A-600 etc.

Assembled Printed Boards

An examination/inspection of assembled printed circuit boards (PCAs) consists of the visual interpretation of the conformity/compliance with the minimum requirements described in the various specifications of the printed circuit boards, such as for example; customer-specific criteria, IPC-A-610, J-STD-001, etc.

Cable & Wires

An examination/inspection of cable, wire and harness assemblies consists of the visual interpretation of the conformity/compliance with the minimum requirements described in the various specifications of the cable, wire and harness assemblies, such as for example; customer-specific criteria, IPC/WHMA-A-620, etc

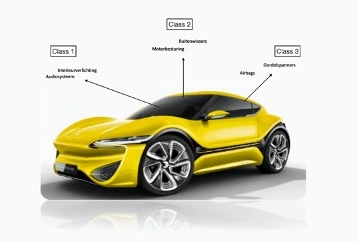

Inspection according to IPC Classes

Inspection requires agreement on the Class to which the products belongs.

Class 1 – General Electronic Products

Class 2 – Dedicated Service Electronic Products

Class 3 – High Performance/Harsh Environment Electronic Products

All INSPECTIONS ARE DONE BY A CERTIFIED IPC TRAINER (CIT) AND/OR MASTER IPC TRAINER (MIT)

All our staff have many years of experience working with and training inspectors, quality engineers etc. according to IPC standards in all IPC Classes. Licensed IPC Training Centers and their staff (MITs, and CITs) are periodically audit to ensure compliance with IPC Policies and Procedures.

Sample lot based inspections

For inspections, ETECH recommends the international inspection standard ANSI Z.1.4-2003 (ANSI Sampling Table) to determine the number of units that will be randomly selected for evaluation and the IPC standards for visual inspections. Samples are checked against a detailed inspection plan for appearance, applicable functionality, packaging integrity, workmanship, and your specific requirements. Discovered defects are classified as major, minor, or critical depending on inspection plans. If you have your QC standard and procedure, we have no concern to follow your documentation.

Inspection services reports and results with digital photos can be emailed to you within 48 hours so that you can quickly authorize your suppliers to ship your products.

ETECH has an international reputation for providing independent third-party inspection and testing services. However, our services do not stop with inspection. ETECH can provide you solutions to your entire supply chain from the sourcing, manufacturing to final delivery.

Rely on our electrics and electronics inspection & testing expertise to secure your brand image and consumer loyalty.